Tel:86-0755-23283620,

MP:86-13249062939

service@zundrive.com

S300 Motor AC Drive For 3 Phase 220V/380V Motors

S300 SERIES HIGH PERFORMANCE VECTOR CONTROL MOTOR AC DRIVE

The S300 VFD is the most common and cost effective drive for a wide range of applications including packaging, material handling / conveying, positive displacement pumping, and HVAC systems.

Specification:

Single phase, 220V, 0.4kw to 2.2kw.

Three phase, 220V, 0.75kw to 75kw

Three phase, 380V480V, 0.75kw to 560kw.

Excellent performance with sophisticated hardware design

Software advanced

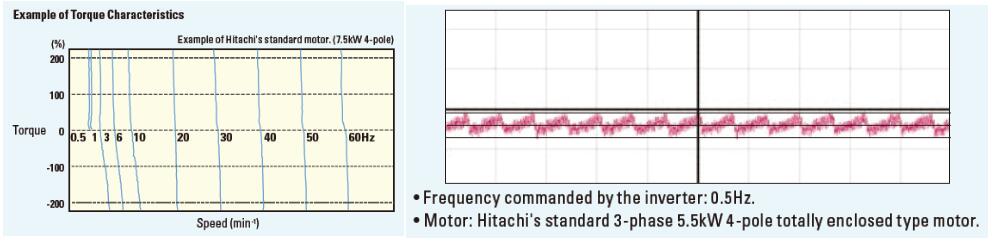

1. Higher performance FVC control mode

Ø Speed control accuracy ± 0.03%

Ø Speed control range: 1:1000

Ø Torque response: < 10ms

Ø Starting torque” 180% rated torque under 0Hz.

2. Compatible with Induction motor and PMSM (permanent magnet synchronous motor)

3. Torque control/Speed control free switch, kinds torque reference giving.

4. Special dead zone compensation to ensure stable torque output when low speed

5. Excellent oscillation suppression function.

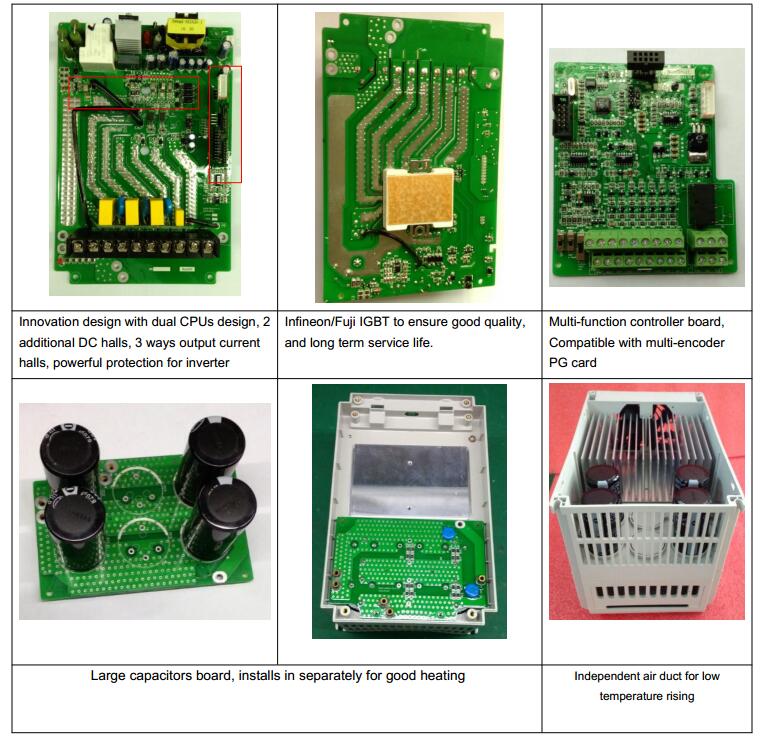

Hardware design

1. Two CPUs design, one CPU for performance control, the other one for function control for better performance.

2. Adding two DC current hall for proving additional DC bus circuit protection

3. 3 way output halls for providing output phase short circuit, ground to phase short circuit

4. Infineon/Fuji IGBT to ensure good quality

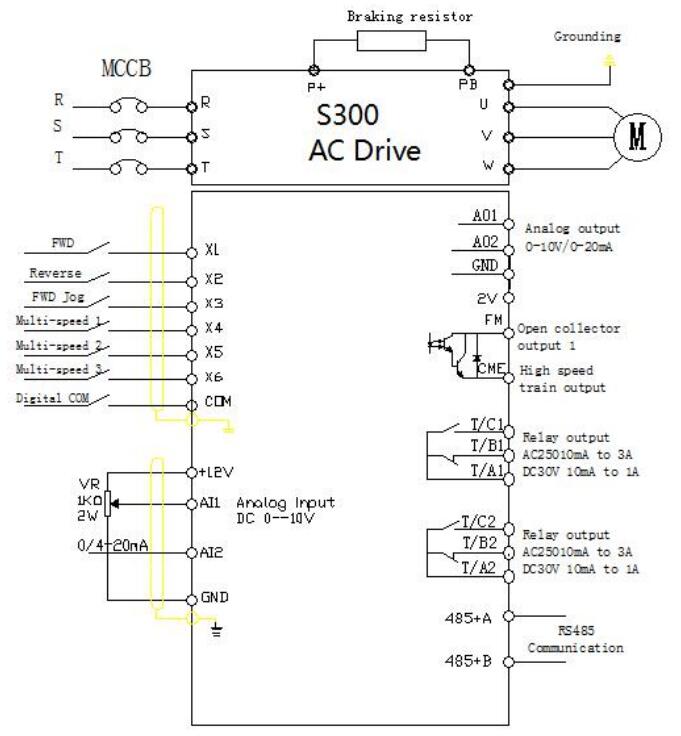

5. 6 way digital input, 2 way analog input, Rs485 input, 2 way analog output ( one for high speed train pulse output)

2 relay output (1 is option), 1 collector output

Excellent Software Performance

1. High starting torque of 180% or greater achieved by sensorless vector control.

Integrated auto-tuning function for easy open loop vector control realizes high torque for applications requiring it is such as crane, lifts, elevators…etc.

2. Speed regulation at low-speed is greatly improved to enhanced process stability and precision.

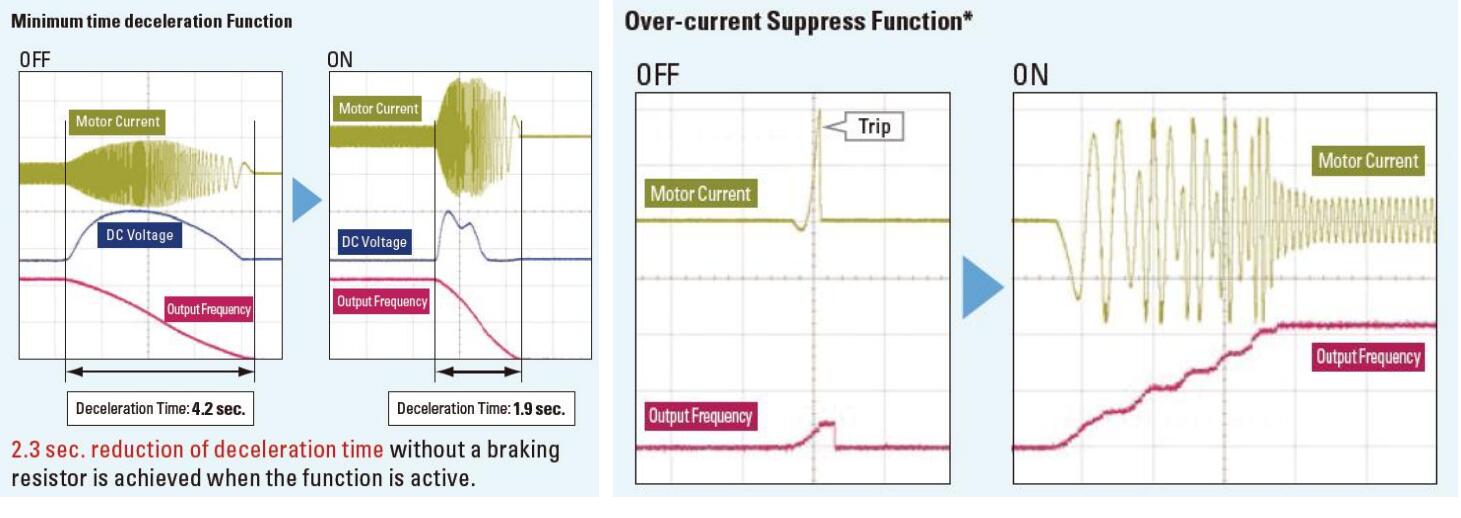

3. Trip avoidance function

Minimum time deceleration, over-current suppress function and DC bus AVR are incorporated. The functions reduce nuisance trips,, Improved torque limiting/current limit function enable a load limit to protect machine and equipment.S

S300 Innovation hardware design:

| Items | Specification | ||||

|

Control mode |

Control mode | V/F control | Sensorless Vector control 1 | Sensorless Vector control 2 | Close loop vector control |

| Starting torque | 1Hz 150% | 0.5Hz 150% | 0.25Hz 150% | 180% under 0Hz | |

| Speed adjust range | ** | 1:50 | 1:200 | 1:500 | |

|

speed stabilizing precision |

±0.1% | ±0.3% | ±0.05% | ±0.02% | |

| Torque precision | NO | NO | Yes | Yes | |

| Motor type | General induction motor,permanent magnet synchronous motor* | ||||

|

Function design |

Highest frequency | General vector control :400Hz V/f control:4000Hz | |||

| frequency resolution | Digital setting: 0.01Hz analog setting: maximum×0.025% | ||||

| carrier frequency | 0.5K~16KHz, the carrier frequency can be adjust by temperature automatically | ||||

| Frequency reference setting method | Digital of Control panel, analog AI1, AI2, potentionmeter of control panel, UP/DN control, communication, PLC pulse frequency | ||||

| Accel./decel. characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | ||||

| V/F curve | 3 mode: linear, multiple points, N Power | ||||

| V/F separation | 2 times separation: totally separation, half separation | ||||

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | ||||

| Braking unit | Built in braking unit up to 15kw, optional is 18.5kw to 75kw, external built in for above 93kw. | ||||

| Jog function | Job frequency range: 0.0 to 50.0Hz, the accel. and decel. time of Jog | ||||

| Configuration PID | Easy to perform pressure, flow, temperature close loop control | ||||

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | ||||

| Common Dc bus * | Multiple inverters use one DC bus for energy balance. | ||||

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | ||||

| Over load tolerance capability |

G type model: 150% rated current for 60s, 180% rated current for 2s, P type Model: 120% rated current for 60s, 150% rated current for 3s. |

||||

| stall control when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | ||||

| Fast current limit function | minimize the IGBT module broken to protect the inverter, maximum reduce the over current fault. | ||||

| Torque limit and torque control | "Excavator" characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | ||||

| features | friendly interface | Display Hello when power on. | |||

| Multiple function key MK.F button | It can set for Forward Jog, reverse Jog, forward/reverse switch | ||||

| Timing control function | A total running time and total running time calculating | ||||

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | ||||

| Command source | Control panel, control terminals, series communication, switch freely. | ||||

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | ||||

| Protection function | Short circuit detect after power on, input/output phase missing, over voltage, over current, under voltage, over heat, over load protection. | ||||

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping | |||

| Altitude | Lower 1000m | ||||

| environment temperature | -10℃~+40℃, power derated for 40~50℃, rated current derated 1% for 1℃increasing. | ||||

| Humidity | Less than 95%, no water condense. | ||||

| Storage | -40~+70℃ | ||||

Application.

Textile: P-jump Winders, Extruders, Tufting Machines, spinning machine

Packaging: In-feed / Out-feed, Case Packing, Bottling & Canning, Carton Manufacturing. Beverage packing

Plastics & Rubber: Extruders, Blow Molding, Thermoforming, Injection Molding.

Pulp & Paper: Paper Machines, Debarkers, Winders, Saw Mills

Converting: Coaters ,Laminators ,Slitters ,Flying Cutters

Air Handling: Supply and Return Fans ,Cooling Towers ,Spray Booths ,Dryers

Oil & Gas: Top Drives ,Pumpjacks, Down-hole Pumping Centrifuges

Material Handling: Conveyors, Sortation, Palletizers, Coil Winding

Metals: Stamping / Punch Press, Wind /Unwind, Cut-to-length,cable drawing. Wire Draw

Construction Materials: Kilns, Planers, Flying Cutoff, Mixers

Laundry: Dryers, Extractors, Folders, Washers

Food & Beverage: Conveyors, Fillers, Mixers, Centrifuges

Automotive: Stamping, Test Stands, Indexing, Metal Cutting

Construction crane, hoist, lifting,

S320 AC DRIVE WIRING AND CONNECTION.

S300 series variable speed drive size.

Item:0

Item:0

.jpg)